There are multiple ways how are soles attached to shoes. which one was used for your boots depending on the exact design of the boot and the design of the sole, as well as who made it. And not everyone does the same things the same way!

You’ll often find that work boots are usually built a little more sturdily than a lot of fashion boots and shoes. but some heritage boots for casual wear are made just as tough as work boots. Now explain the soles attached to the shoes.

Construction methods:

There are three predominant approaches to soles attached to shoes: cementing, flexible welding, and Goodyear welding. We use black and unique Goodyear manufacturing strategies.

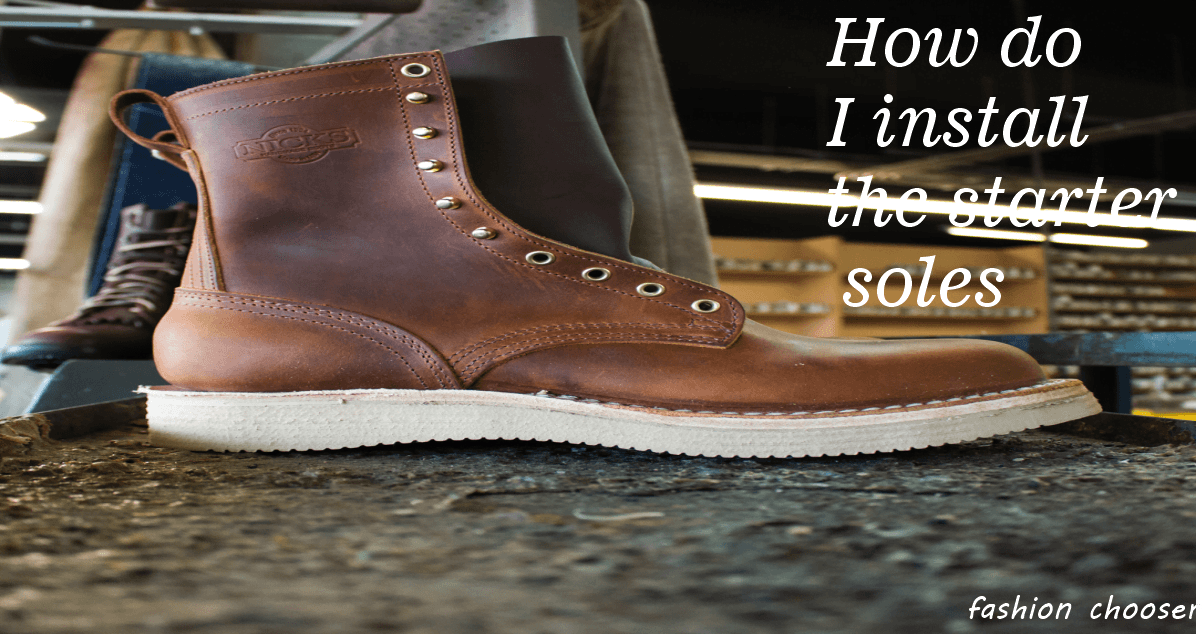

How do I install the starter soles?

There are several ways to connect the launch bases. Not everyone does the same thing in the same way!

Then many fashionable shoes.

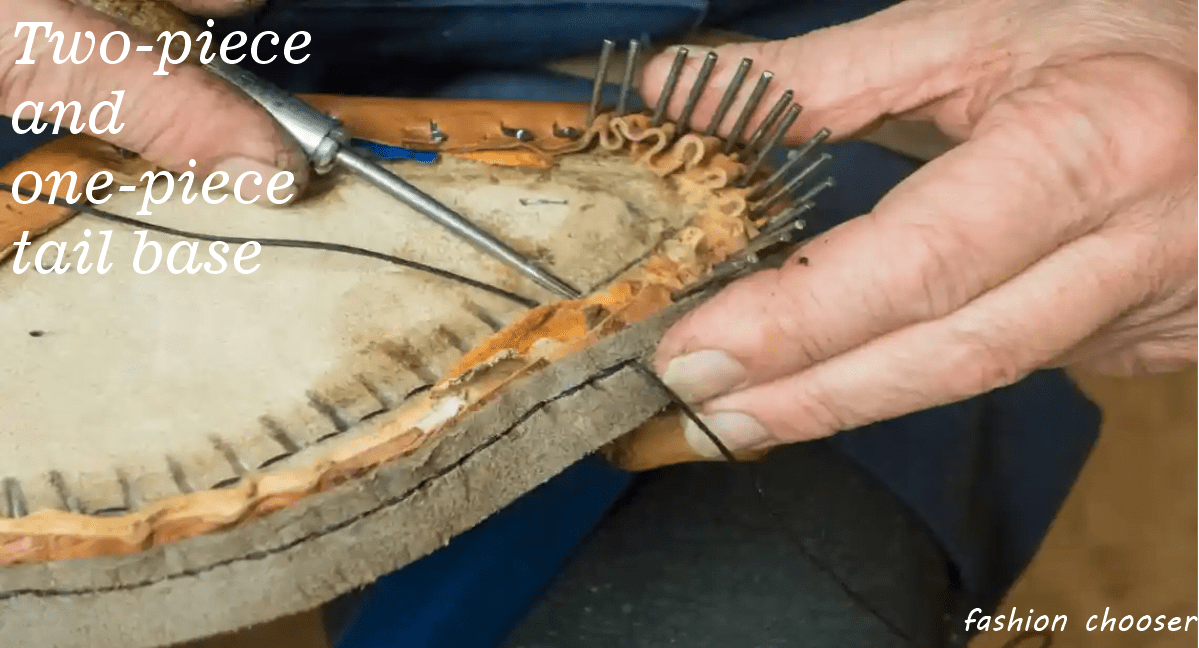

Two-piece and one-piece tail base:

Before moving directly to how they may be positioned. We should point out that the soles of the shoe encompass one or two components. This absolutely matters to how your footwear are made as assembling two-piece base frequently requires one or more steps (every so often several).

The 2-piece sole comes with a heel block that desires to be positioned after setting on the sole of the shoe. Now and again several layers of fabric are located underneath the base to provide additional aid to the heel, that is a “bunch of heels.”

Single leather material soles attached to shoes:

The leather sole goes perfectly with beautiful leather shoes. It offers these features to lay an effective foundation. Do not resort to a significant thickness to always have light shoes. Due to the peculiar location of the fibers, the skin is resistant to punctures. Finally, despite the inhalation of pressure, the skin guarantees good thermal

They joined together according to a three-dimensional design. This creates a system of ducts and passages for the air. Its physical properties are many, but the most important for its use are:

Ability to breathe due to high hole ratio

Lower specific gravity in terms of thickness and surface area is almost translated into light

Significant thermostatic strength with thermal protection of the foot

High puncture resistance due to the special asymmetrical arrangement of nesting fibers in a three-dimensional way

Better designed to maintain the electrical balance of organisms after weak insulating power for electricity.

Eva Sole Material soles attached to shoes:

Ethylene and vinyl acetate. The ratio between the two components and the percentage of cross-references, load agents, and extensions. Add them to the composition to determine the performance characteristics. Eva is ideal primarily for the production of soles and mud ashes. Microporous soles, characterized by lightness, flexibility, and flexibility, tend to retain their original shape.

Most of the bases of the shoe are glued to each other.

In terms of volume, almost all shoes on the market have an installed sole.

Whether the shoe is an all-cement construction. (the shoe shell sticks directly to the base, this is common in imported shoes or synthetic outerwear).

After sewing the top, the shoe factory or manufacturer will mark the top and bottom of the middle sole/base, apply the glue, and press it.

Factory glue and quality control are all that hold shoes together.

For Two Pieces soles attached to shoes:

- Good examples usually nail the entire heel pile at once.

- Heavy builds are what you’re willing to pay extra for and will nail down every layer of the heel stack for maximum stability. They also give the heel a little more stiffness and which helps it overcome more obstacles while walking.

- Alternatively, you can make soles on top

1 thought on “How are soles attached to shoes?”